Services

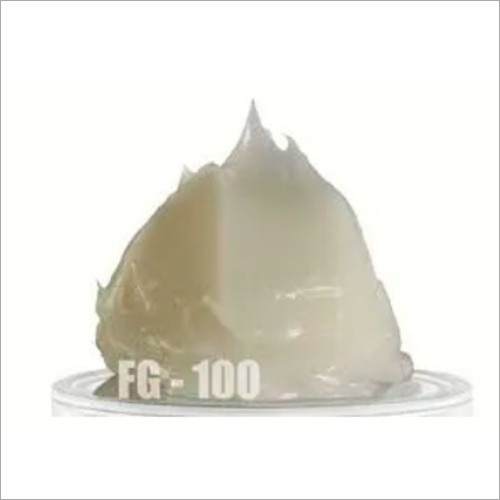

Greases are formulated for reducing friction occurs in the machineries. These are also used for protecting machines from rust, water ingress, wear and other damages. Greases have high viscosity, maximum purity and non-toxicity. Our offered product is easy to apply.

Oils find their usage in fossil-fuel power plants which also includes combined cycle power plants, steam power plants and turbine power plants. These are formulated for protecting as well as lubricating generator bearings. Oils provide protection against wear, corrosion etc.

Welding is a type of process which is performed in automotive, construction, aerospace, energy and other industries. It is helpful in joining thermoplastics, wood and metals. Welding is also capable of creating artwork. Our offering is easy to handle and perform.

Gas cutting equipments provide uninterrupted gas supply, reduce transport cost, easier handling of gas cylinder etc. These are found in medical facility pipeline system for supplying uninterrupted flow of gas. Gas cutting equipments also reduce the need for space.

Aerosol cleaners are best suitable for pipelines, chemical, fertilizer and cement industries. These are also used in refineries, transformer tanks, windmill towers, radiators and power plants. Aerosol cleaners can also be found in bridges and marine applications. can be availed in different varieties.

Coatings are applied on the surface of steels and other materials for providing resistance against corrosion. These are eminent in providing excellent adhesion to steel. Coatings have high resistance to oil, waste water and chemicals. Our provided products are known for efficient protective film.

Sealants PU foams are most commonly found in furniture, construction and automotive sectors. These are found in the making of padded fillers, sofas, thermal insulation, chairs, acoustic absorbent, seats and dashboards. Sealants PU foams are also ideal for sealing frames to windows.

Gasket O rings find their applications in equipment with fluid seal points, fuel systems and more. These are attributed with strong construction, easy installation, low maintenance and corrosion resistance. Gasket O rings are also used for hydraulic seals, air conditioning, ventilation and heating applications.

Fire retardant products are utilized for repairing damages in services, part worn and restoring dimensions of components. Our offered items are suitable for undersized bearing and printing rolls. Fire retardant products have a robust structure, light weight, abrasion resistance and maximum durability.

Cleaners are formulated for removing soils by chemically reacting and dissolving contaminants. These are capable of making the pollutants ready to dissolve in the water. Cleaners are water based and provide maximum efficiency in cleaning procedures. our products have accurate

Send Inquiry

Send Inquiry Send SMS

Send SMS